OCA

OCA (Optical Clear Adhesive) usually refers to optically transparent adhesive film materials, which are divided into rubber type, acrylic type, and silicone type. OCA is colorless and transparent, has a light transmittance of more than 90%, and good bonding strength. It is generally cured by UV irradiation or heating, and has the characteristics of small curing shrinkage.

Classification and Structure

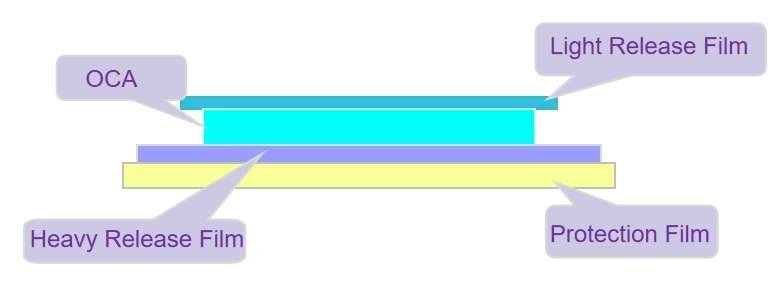

As an important raw material for touch display modules, OCA can be divided into substrate-free and substrate-based materials. The difference lies in whether PET is sandwiched in the adhesive. Substrate-free OCA is made by making optical acrylic adhesive into a substrate-free form, and then attaching a layer of release film to the upper and lower bottom layers. These two layers of release film are also called light release film and heavy release film, as shown in the figure.

OCA optical adhesive is classified by product:

- Used for bonding the upper and lower sensors of the touch screen, the thickness is 25μm or 50μm, usually rolled material;

- Used for bonding the touch screen cover and the sensor, the thicknesses of 75μm, 100μm, and 125μm, usually in sheet form;

- Used for bonding the touch screen or cover to the display module, the thickness is 100μm, 150μm, or 175μm, usually in sheet form.

| OCA type | Can be Produced Thickness |

| Weak acid OCA | 25~500μm |

| Weak base OCA | 25~50μm |

| Heat cured thin OCA | 10~50μm |

| UV cured thick OCA | 50~500μm |

| Organosilicon OCA | 10~150μm |

| Double sided anisotropic OCA | 50~200μm |

| UV barrier OCA | 10~50μm |

Choose of OCA

When selecting OCA, it is necessary to combine product size, structure, application and quality with a comprehensive evaluation to select a suitable OCA optical adhesive to better meet product performance, quality and cost requirements.

Different brands of OCA optical adhesive have slightly different properties, such as different hardness.

Softer adhesive cutting and bonding processes are prone to overflow and wire drawing, making it difficult to repair, but the bonding strength is relatively good; Hard adhesive cutting and bonding processes are easy to control, easier to repair, and have slightly lower bonding strength.

For products that require solar radiation, such as automotive or outdoor products, that need to choose UV-type OCA optical adhesive or heat-curing type that is resistant to solar radiation. Ordinary OCA may produce bubbles or delamination after a period of time after solar radiation.

OCA Bonding Process

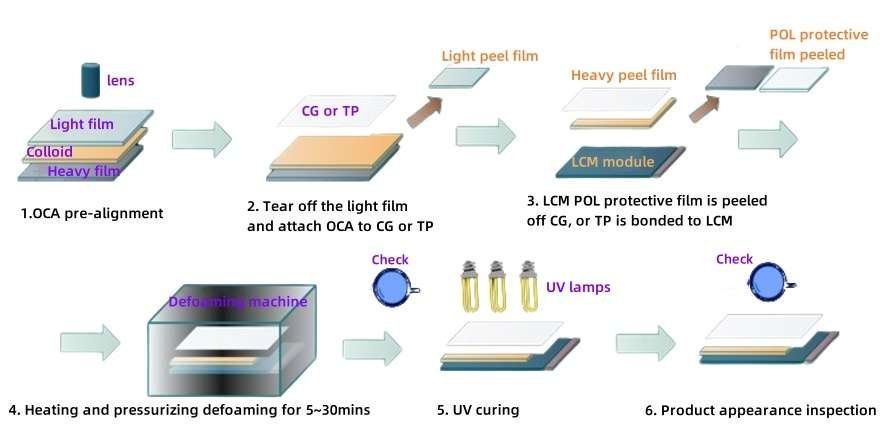

The OCA bonding between touch screens is generally a large sheet bonding process, as shown in Figure 2.

Firstly, align the OCA with the touch screen roll-to-roll, then perform inter touch screen bonding, cut into small pieces, and finally, UV cure and defoaming.

The bonding between the cover glass and the touch screen, as well as between the cover glass and the display screen, generally requires cutting the OCA into small pieces first, then attaching the OCA to the cover plate, and then bonding the cover plate with the touch screen and the cover plate with the display screen, UV curing and defoaming.

UV Curing

The traditional curing method mainly uses tribute lamps or halogen lamps, which have a wide wavelength range (such as 340-800nm), high curing efficiency, and can be suitable for different types of OCA curing. Many OCAs have a main curing wavelength of 365nm and a total energy of 2000-4000mJ/m2.

With the thinner of products and increasing quality requirements, there are currently more and more LED cold light sources used, which have high luminous efficiency, less heat release during the curing process, lower temperature control, and shorter curing time.

Automatic bonding equipment generally chooses LED cold light sources. However, the wavelength of LED lights is relatively single, and suitable LED cold light sources need to be selected based on the curing wavelength of OCA.

Advantages of OCA Performance

1. High bonding and peeling strength, suitable for bonding many transparent film substrates to glass, resistant to high temperature, high humidity and UV light. It can be cured at room temperature or medium temperature with small curing shrinkage;

2. Controlled thickness, providing uniform spacing;

3. Good durability, no yellowing, no delamination or degradation;

4. Light transmittance>92-99%;

5. Refractive index 1.48;

6. Haze 0.1%, low acidity;

7. Bonding to smooth or textured surfaces with strong adhesive force.

Disadvantages of OCA Process

The surface of OCA film is sticky, and it is easy to leave marks on the surface when peeling off the release film, and it is easy to generate bubbles when bonding; it is easy to absorb dust and impurities, causing secondary pollution.

During the bonding process of OCA film and FILM, uneven manual lamination pressure can easily cause wrinkles and bubbles. For lamination with G+G, a vertical pressure combination machine is used, and the air under heating and pressure is difficult to remove, which is very easy to produce bubbles , and the defoaming machine is not effective.

OCA has poor flow properties, and it is difficult to fill the grooves of ITO lines or fill in ink when laminating to sensors or cover glasses.

OCA is not suitable for bonding large-size screens, as it has low production efficiency and high labor costs. OCA attaching G+G is difficult for medium sizes (about 10 inches), and it is difficult for large sizes (such as 15.6 inches and above), and the difficulty increases as the size increases. The production efficiency is low and the yield rate is also low.

After OCA is attached, it cannot effectively increase the strength and explosion-proof capabilities of the screen. Especially for OGS, the explosion-proof membrane is required. After bonding, the explosion-proof effect of the screen is not good, it is not resistant to falling, and the screen is easily damaged.

Application

OCA, OCR and OCF

Due to the differences in material morphology, coating or pasting, and post-treatment methods between OCR and OCF using full fit technology OCA, the selection can be made based on comprehensive considerations such as product size, product structure, terminal application, reliability requirements, production equipment, and cost during actual use.

In summary:

Optical Clear Adhesive (OCA) is mostly used in small and medium-sized products such as smartphones, tablets, smart wearables, VR/AR, etc.

Optical Clear Resin (OCR), also known as Liquid Optical Clear Adhesive (LOCA), is commonly used in large-sized products such as tablets, as well as in automotive and industrial high reliability products.

Optical Clear Film (OCF) is applied to transparent optical components and various types of size bonding, especially for large-sized products such as televisions that are fully bonded. Here is a summary of the comparison of OCA tape, OCR adhesive (LOCA), and OCF optical film parameters, as shown in table 2.

OCA vs. OCR vs. OCF

| Compare item | OCA | OCR (LOCA) | OCF |

| Interval control | Depends on OCA thickness and accuracy | hard to control | Can be precisely controlled |

| Glue overflow | No | Yes | No |

| Adhesion | Weaker | Stronger | Generally |

| Repair step difference | There are bubbles | Diffcult to produce bubbles for point touch | Ability better than OCA |

| Segmental Absorption | Generally | Good | Better |

| Efficiency | Generally | Generally | The same equipment can be used for batch and continuous production |

| Bonded product yield | The one-time yield is over than 90% and can be repaired | The first-time yield is less than 90%, making it difficult to repair | The one-time yield is over than 95% and can be repaired |

| Equipment investment | Generally | Higher | Generally |

| Material requirements | No special requirements | Hard to hard material fit | No special security requirements |

| Application | Small size product | Small and medium size products | Various sizes of product |

As the above analysis, in our projects, if optical bonding is required, we often use OCA for a display size under 15.6”; while the size is bigger, OCR is the better option but the cost is a bit higher.

More to learn about related topics: