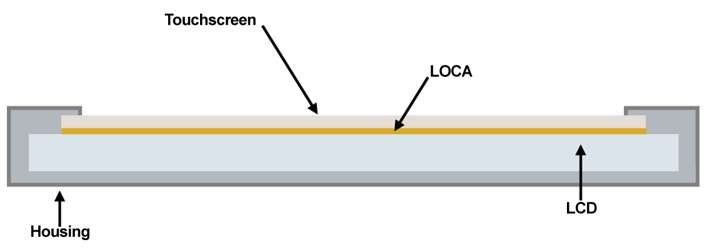

From the structure of the touch display, we can roughly divide the screen into three parts, from top to bottom, the protective glass, the touch screen, and the display screen. These three parts need to be bonded. According to the bonding method, there are mainly two types: air bonding and optical bonding.

Air bonding is also called frame gluing bonding, which simply uses double-sided adhesive to fix the four sides of the touch screen and LCD; there is an air layer between the display and the touch screen.

Optical bonding technology uses optically transparent adhesives to completely and seamlessly adhere the display screen and touch screen together with no air gap.

More details:

What is the Air Bonding and Optical Bonding? How to choose between Air Bonding and Optical Bonding?

According to different forms and coating, optical transparent adhesives can be divided into three types: Optical Clear Adhesive (OCA), Liquid Optical Clear Adhesive (LOCA), and Optical Clear Film (OCF). Hence, their bonding processes are different.

Here we introduce the Liquid Optically Clear Adhesive.

LOCA Bonding Technology

LOCA

Liquid optical clear adhesive (LOCA), also called Optically Clear Resin(OCR), is a liquid-based bonding technology used in touch panels and display devices for bonding transparent optical components, like the cover lens, and plastic.

Property

It is colorless and transparent and can be solidified by visible light, UV, medium and high temperature, moisture, etc.

Key parameters of OCR adhesive properties include viscosity, refractive index, hardness, elongation at break, cure shrinkage, dielectric constant, acidity, and ultraviolet (UV) curing.

OCR adhesive strength is high, but the shrinkage rate is very low, and the hardness is low, which is not prone to shrinkage, faulting, discoloration, and other bad phenomena.

The refractive index of qualified OCR is about 1.5. The refractive index value of 1.53 to 1.54 is basically the same as the refractive index of the cover material, which brings high visibility. The use of OCR makes the overall refractive index of the display part basically the same, reducing the loss of light and interference caused by dispersion and scattering, and reducing the color distortion of the display image.

The hardness index of OCR generally refers to the value after full curing, this value is not the higher the better or the lower the better, to achieve a balance and can improve the overall strength of the product after curing is the most critical.

OCR curing (hardening) shrinkage requirements, the smaller the better, the smaller the shrinkage is less likely to occur shrinkage, faults, discoloration, and other bad influences.

The curing speed of OCR is fast, the pre-curing time is less than 20s, which saves manufacturing time.

The dielectric constant of OCR is usually 1.5 to 3, so the capacitive touch screen using OCR is more sensitive.

The pH value of OCR is 6.5~7.2, which is neutral and non-corrosive to ITO and materials.

Application

It is mainly suitable for bonding of large sizes, curved surfaces or more complex surfaces, and high-reliability automotive display products.

In the design of curved and complex surfaces, tape is difficult to apply but the liquid glue can meet this special requirement. In application situations, such as irregular and uneven surfaces with high ink thickness (such as 3D touch display products) or other structural surface differences, liquid glue is more reliable and can fill all gaps than tape to reduce the issue of bubble rebound.

For example, the bonding of the cover plate to the display modules with thick BL, LOCA makes it easier to solve the problem of filling in gaps with height differences. OCR bonds each functional layer and each module by coating, and then performs thermal curing or light curing. Based on the leveling properties of the liquid, its ability to compensate for step differences is stronger than that of OCA membrane materials.

Besides, filling the gaps between the touch screen, cover, and display with OCR can improve the contrast of the entire display module. Compared with the traditional method of using air gaps, the optical resin can suppress light scattering caused by external lighting and backlight. The optically transparent resin molded by the rapid reaction to UV irradiation has a refractive index and light transmittance similar to glass, is resistant to yellowing, is soft and can withstand the expansion and contraction of a variety of different substrates, and can solve problems caused by high and low-temperature changes during lamination.

Bonding processes

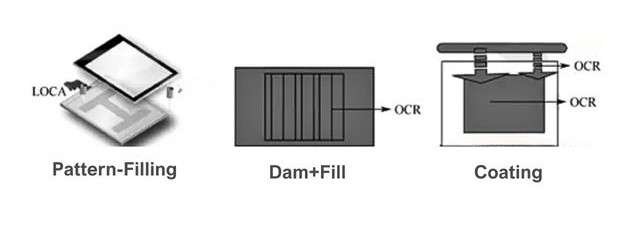

OCR has three types of adhesive application processes: pattern-filling, Dam+Fill, and coating.

Pattern-filling

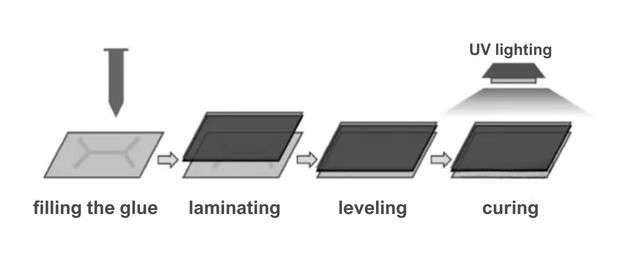

The pattern-filling process has two schemes: natural curing and electrostatic curing.

In natural curing, it first performs edge curing, and then whole curing.

Electrostatic curing achieves curing through the electrostatic action of positive and negative electrodes.

The pattern-filling process is simple and can correspond to a wide range of product models, but the coating is not uniform enough and there are air bubbles concern.

Dam+Fill

In Dam+Fill, there are anti-overflow barriers.

First, OCR is pretreated by ESC electrostatic or ASC adsorption in the vacuum chamber, and then in turn for self-treatment, defoaming, and lamination. ESC electrostatic pretreatment can be coated with glue evenly, so the light transmittance is strong, ASC adsorption pretreatment in the process of adsorption will leave air, and light transmittance is lower.

Dam+Fill process is more complex and applicable to cell phone products, but there are also uneven coating and bubble residue problems.

Coating

In the coating process, OCR is sprayed onto the glass from small holes in the pipeline, and is first pretreated with side curing or full curing, and then flattened with rollers.

The coating process is particularly complex, with minimal use of OCR, easier flow control when spraying OCR, uniform coating, and no air bubbles.

Advantages and Disadvantages of LOCA Bonding

Advantage

The LOCA is colorless and transparent, with a light transmittance of over 98%, it can be cured at room or medium temperature. It also has the characteristics of low curing shrinkage and resistance to yellowing.

Compared with traditional OCA glue, LOCA has special advantages in certain application areas and can solve the limitations faced by OCA.

Characteristics of liquid optical glue LOCA:

1) High transmittance (total transmittance>99%).

2) High bonding strength, easy to fold, and repair unqualified bonding parts.

3) High adhesion, high weather resistance, water resistance, high-temperature resistance, and UV resistance.

4) Can be used in ultra-wide temperature applications such as automotive products.

Disadvantage

When LOCA is cured, it is difficult for the frame and FPC to be fully cured and need to be cured again.

LOCA glue overflow is difficult to control and difficult to clean. Especially for large-size panels. It will cause high production costs and lower production efficiency.

The LOCA process is relatively complex and requires dispensing patterns, pre-curing, curing, and other processes. The product needs to be transported to different sites three to four times. The labor cost of production is also higher.

During the curing process of LOCA, movement on the conveyor belt may cause displacement. The larger the sensor or coverslip area, the easier it is.

Summary

LOCA bonding is a robust technology that Tailorpixels has been providing to various industries for over a decade. Tailorpixels engineers utilize proprietary processes and adhesives to provide bonding solutions for specific display requirements. To learn about other display bonding technologies, read the following articles:

What is the Air Bonding and Optical Bonding? How to choose between Air Bonding and Optical Bonding?