AMOLED has become a leading display technology due to its self-emissive structure, high contrast, fast response, and design flexibility. Here, we introduce the core architecture of this technology.

What are the core advantages of AMOLED?

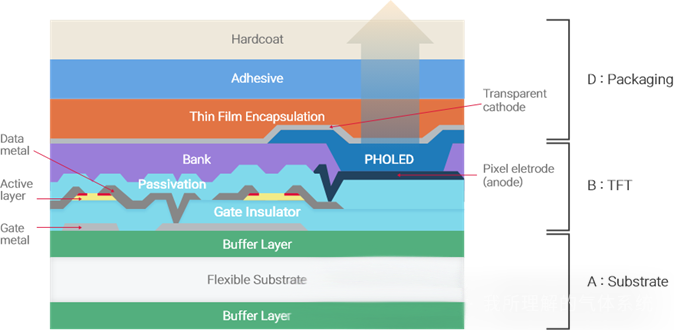

AMOLED display technology, known for its self-emissive characteristics, high contrast, wide color gamut, and flexible form factor, has become the mainstream choice for small and medium-sized consumer electronics. Compared with traditional LCD screens that rely on backlight modules, each pixel in an AMOLED panel emits light independently and consumes almost no power when displaying black. Its structure is simpler, and it offers significantly better viewing angles and response times. The core structure of an AMOLED display consists of the TFT backplane, the OLED light-emitting layer, and thin-film encapsulation (TFE).

Why do modern AMOLED displays require LTPS or Oxide backplanes?

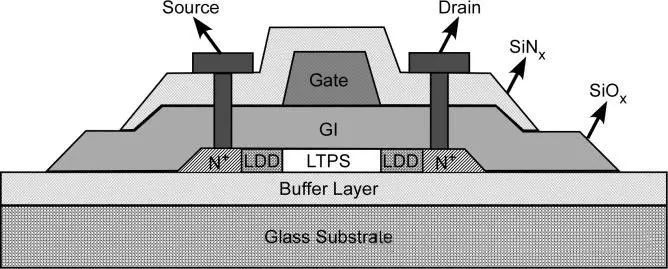

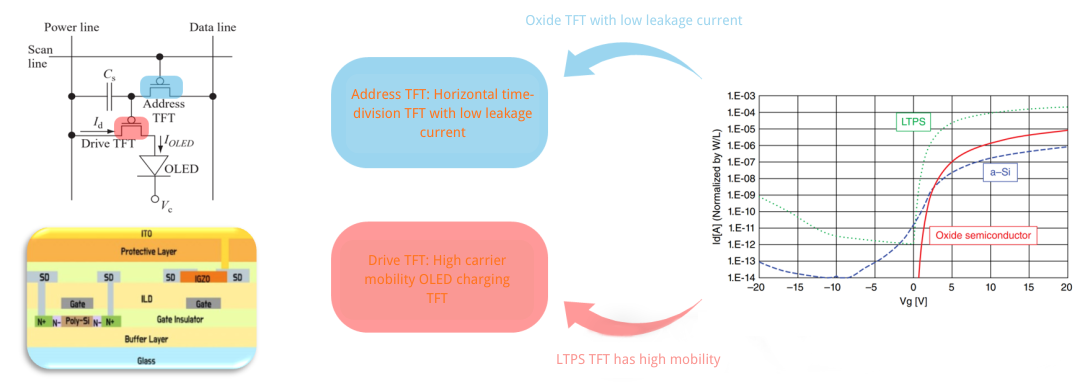

Backplane technology plays a crucial role in achieving high-quality AMOLED displays. Early amorphous silicon (a-Si: H) TFTs struggled to effectively drive OLED pixels due to low carrier mobility and insufficient stability. Today, the industry primarily relies on two backplane solutions: low-temperature polycrystalline silicon (LTPS) TFTs and oxide TFTs. LTPS provides high carrier mobility, making it suitable for driving OLED emission, while oxide TFTs offer low leakage current, helping maintain stable pixel states.

How does LTPO achieve dynamic refresh rates and reduce power consumption?

Apple’s LTPO (Low-Temperature Polycrystalline Oxide) technology, introduced in 2018, combines the strengths of both LTPS and IGZO TFTs. By integrating these two transistor types, LTPO enables dynamic refresh rate adjustment, significantly reducing display power consumption. It has since become a signature technology in high-end AMOLED panels.

How to solve the “burn-in” problem of OLED?

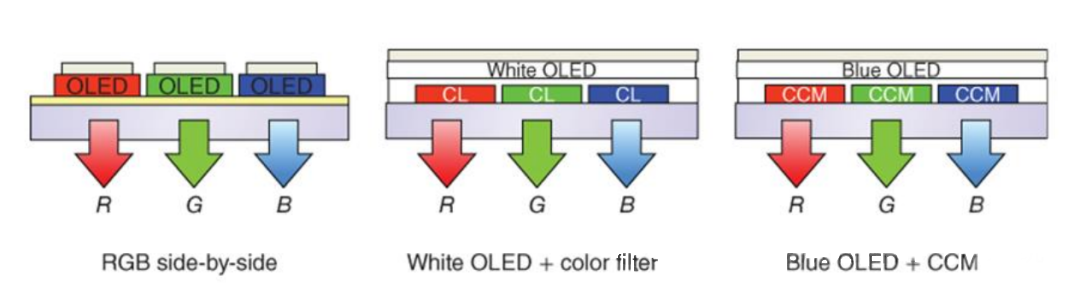

To address the “burn-in” issue caused by the uneven aging of organic materials, the industry has developed multiple color-rendering solutions.

How do WOLED and QD-CC achieve a balance between color and lifespan?

WOLED (White OLED) uses a white light-emitting layer paired with a color filter (CF) to generate RGB colors, ensuring consistent aging across sub-pixels. Another approach is blue OLED + quantum-dot color conversion (QD-CC), in which blue OLED emission excites quantum-dot materials that convert part of the light into red and green.

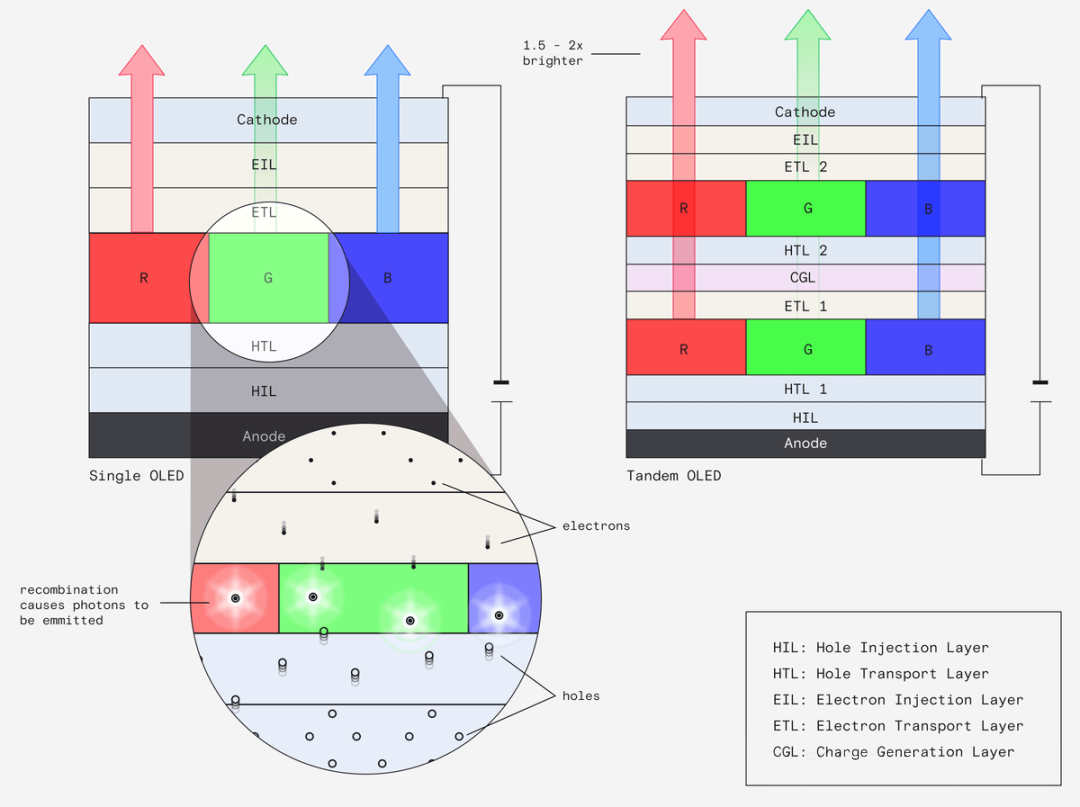

How does a series structure improve brightness and lifespan?

In addition, tandem OLED structures—which stack multiple emissive units through charge-generation layers (CGLs)—increase luminance and extend device lifetime. These innovations have supported the mass production of leading technologies such as WOLED and QD-OLED.

Is MicroLED the ultimate challenger to AMOLED?

Looking ahead, MicroLED is considered a key direction for next-generation displays. It uses inorganic materials such as gallium nitride to form micron-sized LED emitters with long lifespan, high efficiency, and extremely high brightness. Like OLED, MicroLED is self-emissive and eliminates the need for backlights and color filters, making it especially promising for AR/VR applications. Although challenges remain—particularly in high-precision mass transfer and cost reduction—its performance advantages are substantial.

Where will display technology go in the future?

Whether through continuous LCD optimization or the rapid evolution of AMOLED and MicroLED technologies, the display industry continues to push visual performance forward while providing diverse options for customized LCD modules and emerging display applications.

We are the supplier of small AMOLEDs, which are popularly adopted by our customers in their projects, like smart watches, high-end wigs, etc., to enhance the visual experience of the end users from their products.